Introduction

The Roman brick industry was a vital component of the empire's architectural and economic landscape. As the empire grew, so did the demand for building materials, leading to the rise of a thriving brick production industry.

Bricks would become the building material of choice in the later Roman Empire

Brickworks sprang up across the Roman territories, supplying bricks for a wide range of construction projects. These varied in scale and organization, from small family-owned operations to large state-controlled enterprises.

The use of bricks in Roman architecture revolutionized construction techniques and allowed for greater flexibility in design. From humble homes to monumental public buildings, the widespread use of bricks would significantly influence the character and appearance of Roman cities and towns going forward.

Origin and Evolution

Brick manufacturing in ancient Rome was perfected during the first century AD. The Romans refined techniques borrowed from earlier civilizations, developing standardized production methods. They introduced fired bricks, which were more durable than the sun-dried mud bricks used previously.

Roman brickmakers began marking their products with stamps, indicating the manufacturer and sometimes the date of production. This practice helped ensure quality control and allowed for tracking of materials.

By the middle of the first century AD, brick had become the favored building material in Rome. Its popularity grew rapidly, spreading throughout the empire over the following centuries.

Major Brick Production Centres in the Roman Empire

Brick production facilities were established across Roman territories to meet growing demand. Italy, particularly the area around Rome, was a major center of brick manufacturing. Large-scale brickyards operated near clay deposits and transport routes.

Other significant production areas included:

These regional centers developed local variations in brick size, color, and composition based on available materials and local building practices.

The Byzantine Empire continued the Roman brickmaking tradition after the fall of the Western Roman Empire in 476 AD, while the practice largely disappeared in Western Europe for several centuries. However, Roman bricks were commonly reused in medieval Europe and later periods across the former Roman Empire.

Types of Roman Bricks and Tiles

Roman builders utilized various brick and tile types, each serving specific architectural purposes. These included standard bricks for walls, large flat tiles for flooring, and specialized roofing components.

Lydius Brick

Roman bricks known as Lydius were rectangular in shape and commonly used for wall construction. They measured approximately 1.5 Roman feet long by 1 Roman foot wide (44.4 cm x 29.6 cm). Lydius bricks were thinner than modern bricks, typically about 4-5 cm thick.

These bricks were often laid in courses alternating with mortar layers. Their large, flat surface area allowed for quick and efficient wall building. Lydius bricks provided excellent stability and insulation properties.

Builders sometimes arranged them in decorative patterns, creating visual interest in facades. The standardized size facilitated mass production and ease of transport across the empire.

Bipedalis Brick

Bipedalis bricks were large, square tiles measuring two Roman feet on each side (about 59.2 cm). These substantial bricks served multiple purposes in Roman construction.

Architects frequently used Bipedalis bricks for:

- Flooring in upper stories

- Creating level surfaces for mosaics

- Bonding courses in walls

- Lintels over doorways and windows

Their considerable size and strength made them ideal for spanning gaps and distributing weight. Bipedalis bricks also featured in hypocaust systems, forming the suspended floor in heated rooms.

Tegula and Imbrex Roofing Tiles

Roman roofing systems employed two complementary tile types: Tegula and Imbrex. This combination provided excellent weather protection and durability.

Tegula:

- Large, flat tiles with raised edges

- Laid in overlapping rows

- Channeled rainwater downwards

Imbrex:

- Semi-cylindrical tiles

- Placed over the joints between Tegulae

- Prevented water ingress at seams

This roofing method proved so effective that variations are still used today. The tiles were typically made of terracotta, though stone versions existed in some regions.

Manufacturing Techniques

Roman brick production involved sophisticated methods that ensured durability and standardization. The process required careful material selection, precise molding techniques, and controlled firing to create bricks of consistent quality.

Material Selection and Sourcing

The Romans were meticulous in choosing raw materials for brick production. Clay was the primary ingredient, often sourced from local deposits. They preferred clay with specific properties, such as plasticity and mineral content, to ensure optimal brick quality.

Additives like sand, straw, or crushed pottery were sometimes mixed with clay to improve brick strength and reduce shrinkage during drying. The composition varied based on regional availability and intended use of the bricks.

Quality control began at the sourcing stage. Roman builders tested clay samples to determine their suitability for brick-making, ensuring consistent results in the final product.

Moulding and Shaping

Roman brickmakers employed various techniques to shape their bricks. Wooden molds were commonly used, allowing for standardized sizes and shapes. These molds could produce bricks in different forms, including square, rectangular, triangular, and round shapes.

The clay was placed into wooden molds before being fired in a kiln

The clay mixture was pressed into molds by hand or using mechanical devices. Excess clay was scraped off to ensure uniform thickness.

For specialized architectural features, custom molds were created. This allowed for the production of curved bricks for arches or decorative elements with intricate designs.

Drying and Firing Processes

After molding, bricks underwent a crucial drying phase. They were typically air-dried in covered areas to prevent cracking from direct sunlight. This process could take several weeks, depending on weather conditions.

Once sufficiently dry, the bricks were fired in kilns. Roman kilns were sophisticated structures capable of reaching the required high temperatures. The firing process lasted several days, with temperatures carefully controlled to achieve optimal results.

Different firing temperatures produced varying brick qualities. Lower temperatures resulted in softer bricks suitable for interior use, while higher temperatures created harder bricks for exterior construction. The Romans' mastery of firing techniques contributed significantly to the durability of their structures, with many still lasting to this day.

Economics of Brickmaking in Ancient Rome

The Roman brick industry was an important component of the economy. It involved extensive trade networks, large-scale production, and a complex system of ownership and labor.

Trade and Distribution Networks

As stated earlier, brick production in ancient Rome relied on carefully selected clay sources near to manufacturing sites. This close proximity reduced transportation costs and improved efficiency.

Major urban centers like Rome had high demand for bricks, necessitating a robust distribution system. River transport was favored for moving large quantities of bricks over long distances.

Brick stamps provide evidence of widespread trade. These markings indicate the origin and sometimes the destination of bricks, revealing extensive commercial networks across the empire. Some high-quality bricks were exported to distant provinces, demonstrating the value placed on Roman construction materials throughout the empire.

Scale of Production

The Roman brick industry operated on an impressive scale. Large brick factories employed numerous workers and slaves, known as figlinae, to meet the empire's construction needs.

Imperial involvement in brick production was significant. The imperial family owned many brickyards, contributing to the industry's growth and standardization.

Production volumes were immense. Major building projects in Rome could require millions of bricks, driving constant demand and production.

Seasonal factors influenced brick manufacturing. Production typically peaked in summer months when weather conditions were optimal for drying and firing bricks.

Architectural Uses of Roman Bricks

Public Buildings and Monuments

Roman bricks were extensively used in the construction of grand public edifices. The Pantheon in Rome showcases the impressive use of brick in its massive dome and walls. Bricks were often employed in the core of walls and vaults, later faced with marble or stucco for a more ornate appearance.

Amphitheaters, such as the Colosseum, incorporated brick arches and vaulting in their complex structures. Public baths, such as the Baths of Caracalla, utilized brick for their intricate heating systems and large halls.

The Baths of Caracalla in Rome

Domestic Architecture

In Roman homes, bricks played a crucial role in both structural and decorative elements. A wealthy urban dwelling, known as a domus, often featured brick walls covered with frescoes or marble veneers.

Apartment buildings, or insulae, relied heavily on brick construction for their multi-story structures. These buildings housed the majority of the urban population in ancient Rome.

Brick was also used in flooring, creating durable and sometimes decorative surfaces. Hypocaust systems, used for underfloor heating, were constructed using brick pillars and tiles.

Rural villas incorporated brick in their walls, arches, and vaulted ceilings. These country estates often featured elaborate brick patterns in their designs.

Military Structures

Roman military architecture made extensive use of bricks for their fortifications and camps. The iconic Hadrian's Wall in Britain incorporated brick courses in its stone construction, enhancing its strength and durability.

Forts and watchtowers along the empire's borders utilized brick in their walls and towers. These structures needed to be built quickly and efficiently, making brick an ideal material.

Military barracks within camps were often constructed entirely of brick. These standardized buildings could be rapidly assembled to house troops across the empire.

Granaries and storage facilities in military settlements relied on brick construction to create sturdy, weather-resistant structures for preserving food and other supplies.

Innovations and Technological Advancements

Introduction of the Arch

The Roman arch stands as one of the most influential architectural innovations in history. This curved structure allowed for the distribution of weight across a wider span, enabling the construction of larger and more stable buildings. Roman engineers perfected the arch design, incorporating it into aqueducts, bridges, and monumental structures like the Colosseum.

The true arch, made of wedge-shaped stones called voussoirs, was a game-changer. It could support heavier loads and span greater distances than traditional post-and-lintel systems. This innovation led to the development of vaulted ceilings and domes, expanding architectural possibilities.

The Romans also introduced the segmental arch, which allowed for even wider spans and reduced material usage. This type of arch became crucial in the construction of bridges and aqueducts, facilitating the expansion of Roman infrastructure across their vast empire.

Hydraulic Cements and Concrete

Roman concrete, known as opus caementicium, was another revolutionary building material. Its durability and versatility surpassed traditional construction methods, allowing for the creation of massive structures that have endured for millennia.

The key to Roman concrete's strength lay in its unique composition. It combined lime, volcanic ash (pozzolana), and aggregate materials. This mixture, when combined with water, underwent a chemical reaction that resulted in an incredibly strong and durable substance.

Roman engineers discovered that adding volcanic ash to the mix created a hydraulic cement that could set underwater. In fact, thanks to chemical reactions between seawater and the volcanic ash, the concrete actually gets stronger over time. This innovation enabled the construction of harbors, breakwaters, and other marine structures which greatly increased the volume of maritime trade.

The use of concrete also allowed for more efficient construction techniques. It could be poured into wooden forms, enabling the rapid creation of complex shapes and structures.

Brick Production Markings and Stamps

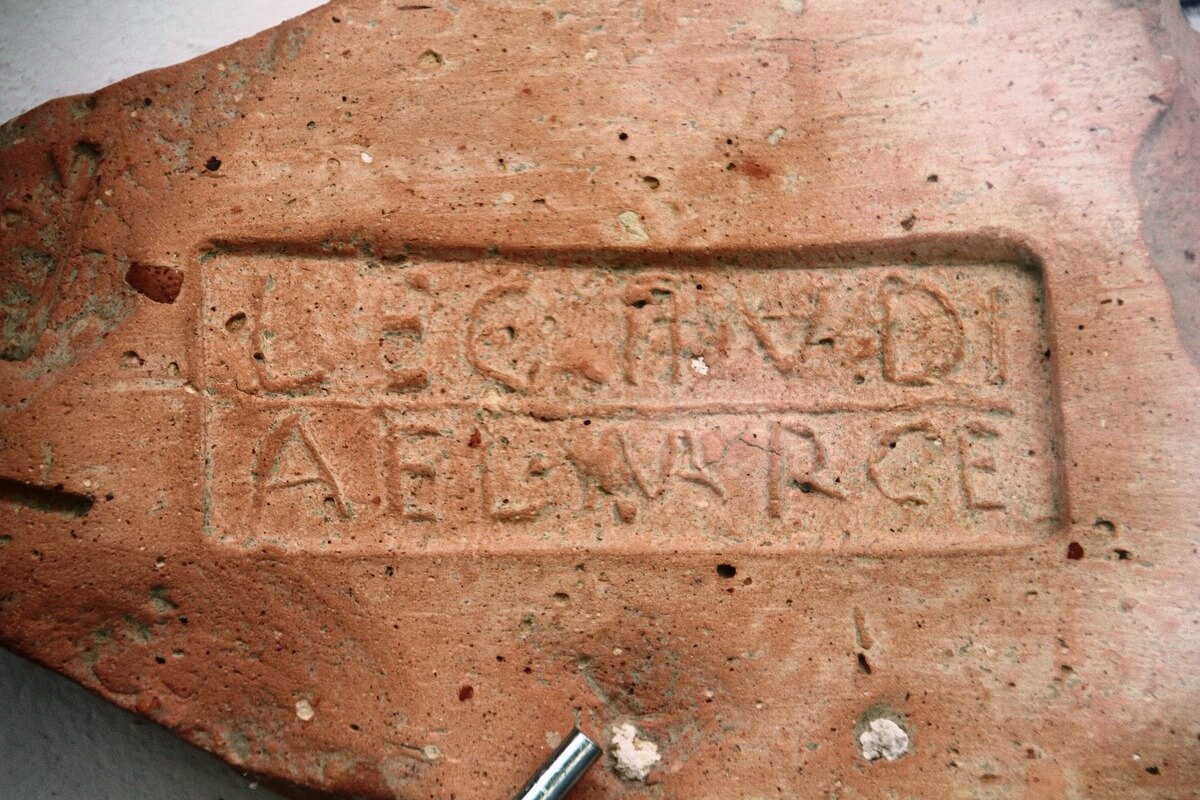

As mentioned earlier, Roman bricks often featured distinctive markings and stamps that provided valuable information about their origin and manufacture. These identifiers played a crucial role in the organization and management of the Roman brick industry.

Brick stamps served multiple purposes in ancient Roman construction. They indicated the producer or workshop responsible for manufacturing the bricks, helping to ensure quality control and accountability. Some stamps included dates, allowing for precise chronological tracking of building projects.

The stamps also provided information about the brick's intended use or destination. In many cases, they bore the names of high-ranking individuals or even emperors.

Military units frequently marked their bricks, particularly legionary bricks used in fortifications. These stamps helped track production quotas and identified which units were responsible for specific construction projects.

Bjoertvedt, CC BY-SA 4.0, via Wikimedia Commons

A Roman brick with the inscription Legio II Adiutrix on it

The unique designs and text on these stamps allow archaeologists and historians to trace the origins of bricks used in various structures. By studying these stamps, researchers can map the extent of a workshop's influence and the geographic reach of its products. This information provides valuable insights into Roman trade networks and the economic relationships between different regions of the empire.

Quality Control and Standardization

The Roman brick industry implemented strict measures to ensure consistent product quality and adherence to specifications. These practices helped maintain high standards and reliability in construction projects throughout the empire.

Dimensions and Tolerances

Roman bricks were produced with remarkable uniformity. Quality control procedures involved regular inspections during the production process. Workers checked raw materials for impurities and monitored clay mixture consistency. Molds were frequently examined for wear to maintain accurate dimensions.

Finished bricks underwent rigorous testing. Samples were randomly selected and measured to verify compliance with size specifications. Bricks that fell outside acceptable tolerances were rejected or repurposed for less critical applications.

Environmental Impact and Resource Use

The Roman brick industry unsurprisingly had a negative effect upon the local environment through extensive clay extraction and extensive wood burning in kilns. These processes depleted natural resources and contributed to air pollution in ancient times.

Clay Extraction and Soil Depletion

Clay extraction for Roman brick production had substantial environmental consequences. This practice removed valuable topsoil, potentially affecting agricultural land and natural habitats. The removal of clay altered local landscapes, creating pits and changing drainage patterns. These alterations could lead to erosion, localized flooding, and habitat loss for flora and fauna.

Roman brick producers often prioritized accessibility of resources over long-term environmental sustainability. This approach, while efficient for production, contributed to lasting changes in soil composition and land use patterns around major Roman settlements.

Kilns and Fuel Consumption

The firing process in Roman brick kilns also had an environmental impact. Kilns required large amounts of fuel, primarily wood, leading to deforestation of the surrounding area.

The burning of wood in kilns released substantial amounts of carbon dioxide and other pollutants into the atmosphere. While certainly nowhere near the scale of modern industrial emissions, this pollution likely affected local air quality and contributed to early forms of urban smog.

Kiln technology in Roman times was less efficient than modern methods, requiring more fuel per brick produced. This inefficiency exacerbated the environmental impact of fuel consumption and emissions.

The continuous operation of brick kilns to meet high demand in growing Roman cities intensified these environmental pressures over time.

Decline of the Roman Brick Industry

The Roman brick industry faced significant challenges in its later years. Economic shifts and the introduction of new construction methods contributed to its gradual decline.

Economic Factors

The high cost of brick production became a major issue as the Roman Empire's economy weakened. Labor expenses and transportation costs for raw materials increased substantially. These rising costs made brick less competitive compared to other building materials.

Many brick workshops closed due to reduced demand and financial pressures. The specialized workforce involved in brick-making began to diminish. This led to a loss of expertise and quality control in the industry.

Trade routes disruptions further complicated the situation. It became difficult to source clay and other essential materials from distant regions. Local production struggled to meet the same standards as the previously well-established imperial brick yards.

Transition to Alternative Building Materials

As brick production declined, builders turned to alternative materials. Stone became increasingly popular for monumental structures. It offered durability and prestige that brick could not match in certain applications.

Concrete emerged as a versatile and cost-effective option. Roman engineers developed advanced concrete formulas that could be molded into various shapes. This flexibility allowed for innovative architectural designs without relying on brick.

Wood also saw increased use in construction, especially for smaller buildings. It was readily available in many regions and required less specialized labor to work with.

Plus, or course, when budgets became stretched, there was a greater impetus to take materials from older structures to re-use, rather than spend money to make new.

Archaeological Evidence and Research

Archaeologists have uncovered extensive physical evidence of Roman brick production and use. Excavations and analyses provide insights into manufacturing techniques, distribution networks, and the cultural significance of bricks in ancient Rome.

Excavated Brickworks and Kilns

Roman brick-making sites have been discovered throughout the former empire. These excavations reveal the scale and sophistication of the industry. Large-scale production facilities often included multiple kilns, clay preparation areas, and storage spaces for finished products.

Kilns varied in size and design, capable of firing many bricks simultaneously. Archaeologists have found both updraft and downdraft kilns, each suited for different production needs.

Evidence of brick stamps, used to mark products with manufacturer information, provides valuable data on production organization and chronology.

Stylistic and Compositional Analysis

Researchers employ various techniques to study Roman bricks. X-ray diffraction (XRD) and Fourier-transform infrared spectroscopy (FT-IR) are used to analyze brick composition, revealing information about raw materials and firing temperatures.

Stylistic analysis of brick types, sizes, and surface treatments helps archaeologists date structures and trace trade patterns. This information is crucial for understanding architectural developments and economic networks in the Roman world.

Stamped bricks are particularly valuable for research. As mentioned above, the names and symbols on these stamps offer insights into ownership, production management, and the involvement of elite families in the brick industry.

Legacy and Influence on Modern Brickmaking

Roman brickmaking techniques have left an enduring mark on construction practices. Their methods continue to inspire modern builders and architects, shaping the way bricks are produced and used today.

Continuity of Techniques

The Roman approach to brick production has similarities with modern methods. Ancient Romans allowed the clay to ventilate before firing, a practice mirrored in today's brick manufacturing process called maturation. This technique helps regulate moisture content and prevents fractures during firing. While there's no concrete evidence that Romans used identical maturation processes, the parallels are striking.

Modern brickmakers still employ variations of Roman firing techniques. The careful control of temperature and atmosphere in kilns echoes the precision Roman craftsmen achieved centuries ago.

Reproduction and Revival in Modern Architecture

Roman bricks have experienced a renaissance in contemporary architecture. Architects and builders often choose Roman-style bricks for their distinctive appearance and historical resonance.

These modern adaptations are typically longer and flatter than standard bricks, mimicking the proportions of their ancient counterparts. They're used to create visual interest and historical connections in both new constructions and restoration projects.

The durability of Roman brickwork has inspired modern manufacturers to focus on creating long-lasting products. Advanced firing techniques and material selection draw from Roman expertise to produce bricks that can withstand centuries of use.

Architects frequently incorporate Roman brickwork patterns like opus reticulatum and opus vittatum in contemporary designs. These ancient techniques add texture and visual appeal to modern structures, bridging past and present architectural styles.

Pouwerkerk, CC BY-SA 3.0, via Wikimedia Commons

Opus reticulatum pattern at Hadrian's Villa in Tivoli, Italy